Cgq Strong Magnet Line Filter Series

The strong magnetic tube dropper is composed of strong magnetic material with high coercive force and anti-dropping net. Its adsorption force is ten times that of common magnetic material, the ability to Adsorb micron-sized ferromagnetic contaminants, and to overcome the impact of high-speed iron, magnetic contaminants are re-adsorbed, thus avoiding the hydraulic components of the stuck or friction wear, extend the service life of hydraulic components and hydraulic system, enhance the reliability of hydraulic system. In the electro-hydraulic Servo, servo system and electro-hydraulic proportional system application, the effect is very obvious. This product is widely used in electro-hydraulic servo system, electro-hydraulic proportional system and general hydraulic transmission, mechanical equipment of power system, ship, weapon equipment and Hydraulic Test Bench, etc. .

The CGQ series filters have magnets with high coercive force, whose attraction is 10 times stronger than regular magnet, so all the magnetic containments can be removed by this filter at high flow rate. It can be used before the main components and get the reliability of the hydraulic system. This series filters are widely used in electro-hydraulic servo and proportion system.

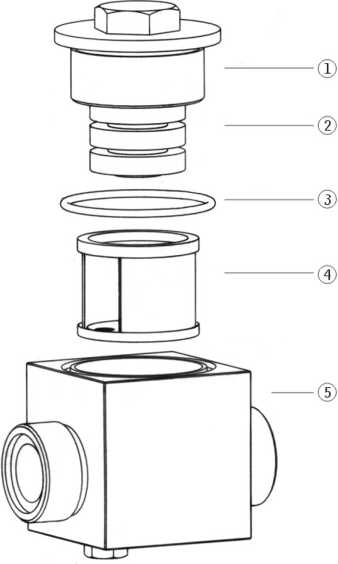

|

Number |

Name |

Note |

|

1 |

Cap | |

|

2 |

Magnet ring | |

|

3 |

O-ring | Wearing parts |

|

4 |

Element | Wearing parts |

|

5 |

Housing |

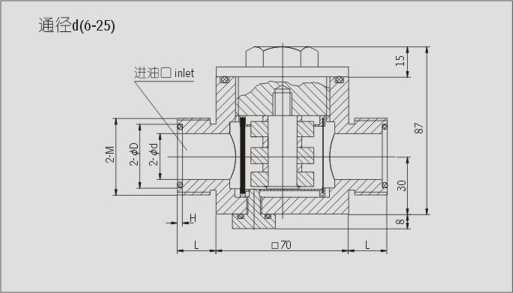

1. Pressure class:31.5MPa

2. Filtration accuracy:60 p m

3. Initial Pressure loss:0.14~0.19MPa

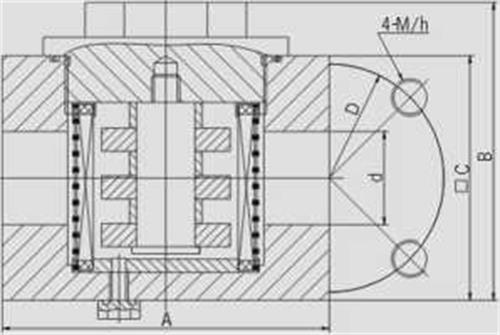

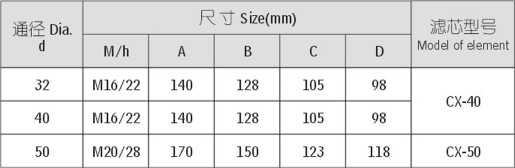

| Dia.

(1 |

Size( mm) |

"O"ring |

Model of element |

|||||

|

M |

D |

H |

L |

|||||

|

6 |

M16 x 1.5 | 11 |

0 -0.2 |

1.4 |

0 -0.05 |

11 | Φ11 x 1.9 |

CX-25 |

|

8 |

M18X1.5 | 12 | 12 | Φ12x 1.9 | ||||

| 10 | M22X1.5 | 16 |

1.8 |

12 | Φ16 x 2.4 | |||

| 12 | M27X1.5 | 20 | 13 | Φ20 x 2.4 | ||||

| 15 | M30X1.5 | 24 | 14 | Φ24 x 2.4 | ||||

| 20 |

M36x2 |

30 | 0 -0.34 |

2.4 |

16 | Φ30 x 3.1 | ||

| 25 |

M42x2 |

34 | 20 | Φ34 x 3.1 | ||||

Note: When the filter is cleaned, the oil hole is first opened to release the internal oil, then the end cover is opened to clean, the magnetic core and the drip net are washed. If the drain screw is screwed tightly before being put into the drip net again, the holes in the UNDERPAN must be aligned to the drain plug.

10mm,CGQ-10o Nom.Dia.:10mm,themodel:CGQ-10.