Luc, Luca, Lucb Pushcart Filter Series

LUC、LUCA and LUCB series of pushcart filters are a special filtration device not only for filtering the oil flowing to a tank but also For filtering the oil in hydraulic ystem. These kinds of filters are made into good structure, easy using and long service life and also have high filtration low noise. As required you may choose different filter element from 3 u m to 30 u m filtration. They are also be used as a by-pass filter outside a hydraulic system.

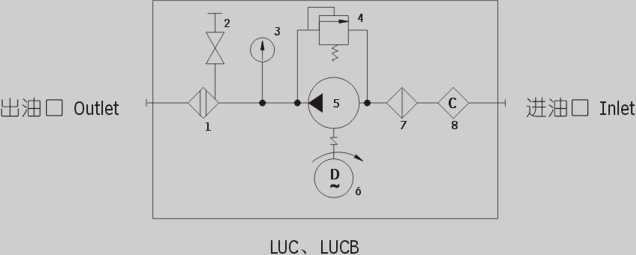

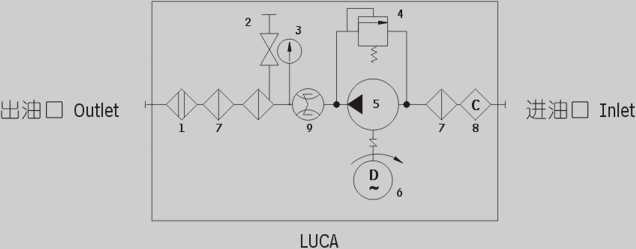

1.Fine filter

2.Discharge valve

3.Pressure gauge

4.Safety valve

5.Pump

6.Motor

7.Rough filter

8. Magnetic filter

9. Flow gauge

luc:Fine pushcart filter

LUCA:5 class fine pushcart filter

LUCB:With jerrican fine pushcart filter

W: Filter media is mesh

Filtration accuracy(n m)

Flow rate(L/min)

BH : Water-glycol Omit if use hydraulic oil

Omit if use filter media is paper

Q:Filter media is fibre

| Model | Flow (L/min) | Rough Filtr.(M m) | Fine Filtr.(M ni) | Initial AP (MPa) | Attraction of magnet (N) | Power of motor(Kw) | Voltage(V) | Weight (Kg) |

| LUC-16 x*# | 16 |

100 |

3 5 10 20 30 |

<0.02 |

2 |

0.37 |

AC:380 |

60 |

| LUC-40 x*# | 40 | 0.75 |

90 |

|||||

| LUC-63 x*# | 63 | 1.1 |

100 |

|||||

| LUC-lOO x * # |

100 |

1.5 |

110 |

|||||

| ALUC }16 x * #D | 16 | 0.37 | ||||||

| LUC g-40 x * # | 40 | 0.75 | ||||||

| LUC }63 x*# D | 63 | 1.1 | ||||||

| LUC g-100 x*# |

100 |

1.5 |

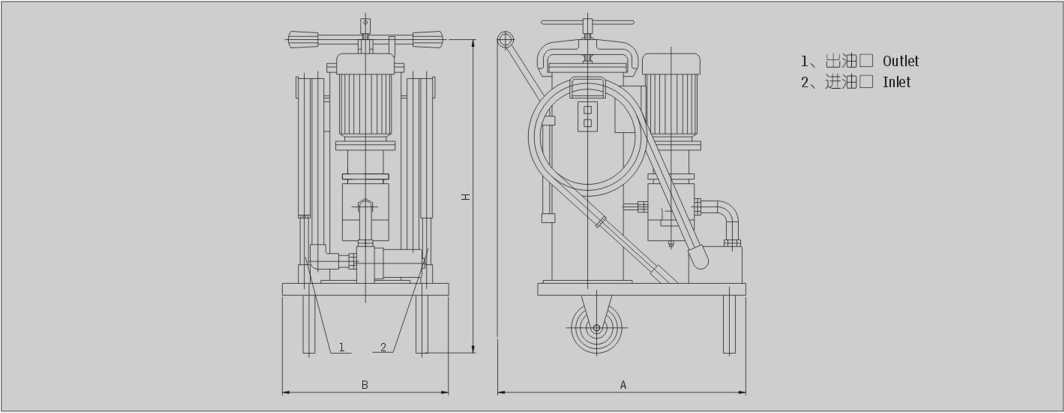

1.LUC series

|

Model |

Size (mm) |

||

|

H |

A |

B |

|

| LUC-16 X* |

920 |

470 |

350 |

| LUC-40 X* |

930 |

648 |

400 |

| LUC-63 X* |

960 |

560 |

400 |

| LUC-lOO X* |

960 |

560 |

400 |

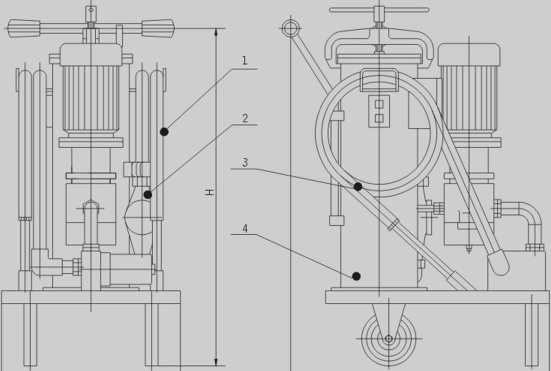

2. LUCA Series

1. Outlet

2. Flow gauge

3. Inlet

4. 3 Class filter

| Model | Size (mm) | ||

| H | A | B | |

| LUCA-16 x * | 1060 | 650 | 450 |

| LUCA-40 x * | 1080 | 700 | 500 |

| LUCA-63 x * | 1120 | 740 | 500 |

| LUCA-100 x * | 1120 | 740 | 500 |

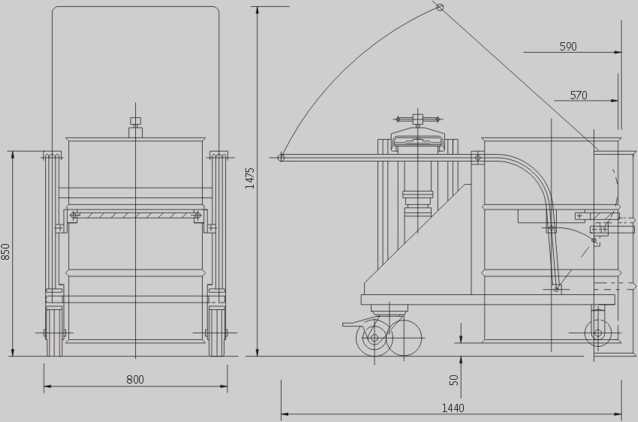

3. LUCB Series

|

Model |

Name of spare parts |

|||

|

Model of rough filter element |

Model of fine Filter element |

Seal(3) HG4-692-67 |

PVC Reinforced hose(Φ 2m) (The inner diameter)mm | |

| LUC-16 x * |

CWU-16 x 100-J |

CZX-16 x * # |

20 x 40 x 10 |

suction,returnΦ19 |

| LUC-40 x * /LUCB-40 x * |

CWU-40 x 100-J |

CZX-40X*# |

25x45x10 |

suction Φ32, returnΦ25 |

| LUC-63 x * /LUCB-63 x* |

CWU-63 x 100-J |

CZX-63 x * # |

25x45x10 |

suction Φ32, returnΦ25 |

| LUC-100 x */LUCB-lOOx * |

CWU-100 x 100-J |

CZX-lOOx *# |

30 x 50 x 10 |

suction Φ32, returnΦ25 |

|

Name of spare parts |

||||||

| Model |

Model of rough filter element |

Fiter Bnowl |

Frame type oil seal(3) Seal HG4-692-67 |

WC Reinforced hose(length 2m) (The inner diameter)mm |

||

|

Model of rough filter elemen I |

Model of rough filter element II |

Model of fine filter element |

||||

| LUCA-16 X * | CWUA-16 x 100-J | CXXA1-16 x 80 | CXXA2-16 x 50 | CZXA-16X *# |

20 x 40 x 10 |

suction,returnΦ19 |

| LUCA-40 x * | CWUA-40 x 100-J | CXXA1-40 x 80 | CXXA2-40 x 50 | CZXA-40X *# |

25x45x10 |

suction Φ32, returnΦ25 |

| LUCA-63 X * | CWUA-63 x 100-J | CXXA1-63 x 80 | CXXA2-63 x 50 | CZXA-63X *# |

25x45x10 |

suction Φ32, returnΦ25 |

| LUCA-100 x * | CWUA-100 x 100-J | CXXA1-100 x 80 | CXXA2-100 x 50 | CZXA-100 x *# |

30 x 50 x 10 |

suction Φ32, returnΦ25 |

|

|

||||||

Note:(1)*is Filtration accuracy. If the fluid is water-glycol, flow rate 63L/min filtration accuracy 5 p m, filter media is paper, the model of pushcart filter is LUC • BH-63 x 5 or LUCA • BH-63 x 5, the model of fine filter element is CZX • BH-63 x 5 or CZXA • BH-63 x 5. # is filter media. Omit if Filter media is paper; Q: Filter media is fibre; w: F- ilter media is mesh.

(2) To ensure the flow of pushcart filter, the customer should select the inside diameter of the hose according to the above table form, and not flatten the hose when worki ng. The height of suction oil should less than 500mm. The suction pipe can not be prolonged; the return pipe can not be longer than 8m.

(3) It means seal of pump shaft.

(1) Avoiding the possible counter rotation of the oil pump while starting the machine, otherwise it may lead to the out blown of the axle seal and entering of air.

(2) Air might be introduced into the machine during the operation and affect the oil flow. To ensure the rated flow and normal operation of the fine filter element, the discharge valve should be opened in time to release the air until oil can be seen at the outletof the discharge valve, then close th e discharge valve closed.

(3) After a certain period of peration, coarse cleaner could be gradually contaminated and noise of pump might occur, you should stop the machine in order to clean the filter element.

(4) Dirt might stick to the elements of fine filter, causing a rise of the pressure in the filter bowl. When the pressure hits 0.4MPa, the elements should be the changed in time.

(5) The suction and oil outlet tube should always be kept clean.

(6) Should the pushcartfilterfail to pump oil, please check:

a. The rotating direction of the pump;

I). Whether the sealings between the tank and oil inlet are properly; the oil inlet is above the oil surface or oil runs out;

c. If the elements of rough filter are stuck.

(7) If the oil flow distinctly reduced, please check:

a. Whether the elements of rough and fine filters are stuck with filth.

I). Whether an out I)lown of the axle seal has occurred due to wear or counter rotation.

(8) If a sudden pressure drop occurs, please check whether the elements of fine filter have been damaged.