Original Factory Hydraulic Oil Level Indicator - OR-MULTI-TUBE Series Oil Pressure Cooler – Xinyuan

Original Factory Hydraulic Oil Level Indicator - OR-MULTI-TUBE Series Oil Pressure Cooler – Xinyuan Detail:

1. Heat transfer to determine the best cooling effect. This cooler adopts multi-tube type, large cooling area, Good cooling effect.

2. The cooling area is full. The cooling area is calculated according to the surface area of the copper tube, so the cooling area is full.

3. Cooler material is most suitable for heat dissipation. Adopt pure red copper tube, heat conductivity is above 0.95.

1. the cooling pipe oil two can freely decide the inlet and outlet, the flow of oil itself is not restricted. The inlet of water must be entered from the bottom and discharged from the upper outlet.

2. Fresh water only. The use of sea water shall be specially customized.

3. Food and chemicals must not be used.

4. water inlet and oil inlet temperature difference in more than 80°C can not be used.

5. the highest pressure: oil side 10kg/cm2, water side 7kg/cm2

6. the water side (heat transfer tube inner surface) for about 4 months or half a year, remove scale once, can maintain a good cooling efficiency. When using high viscosity oil, please keep the amount of oil equal to the amount of water.

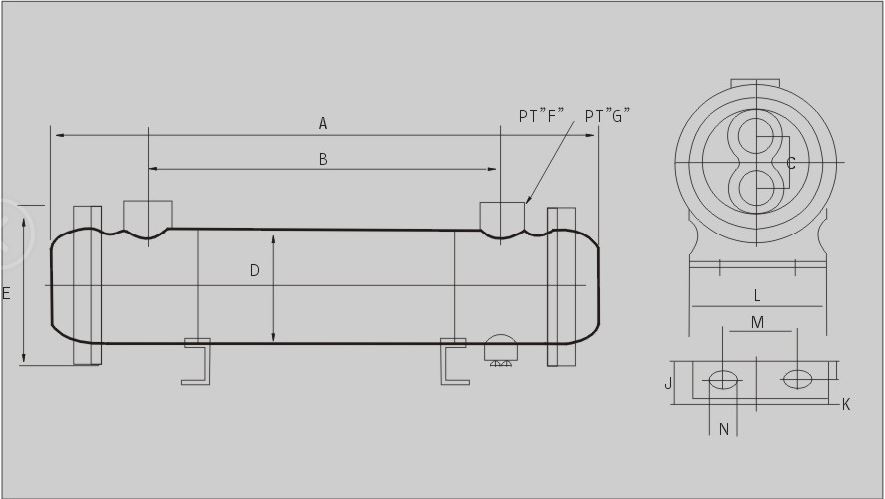

| Model | A | B | C | ΦD | E | F | G | J | K | 4>L | M | N | Traffic |

| OR-60 | 450 | 305 | 46 | 90 | 120 | 3/4″ | 3/4″ | 23 | 11 | 115.5 | 95 | 7×10 | 60 |

| OR-100 | 555 | 403 | 57 | 114 | 150 | 3/4″ | 3/4″ | 33 | 12.5 | 145.5 | 106.5 | 10×20 | 100 |

| OR-150 | 575 | 385 | 76 | 140 | 180 | 11/4″ | 1″ | 30 | 12.5 | 175 | 130 | 13×16 | 150 |

| OR-250 | 780 | 585 | 76 | 140 | 180 | 11/4″ | 1″ | 30 | 12.5 | 175 | 130 | 13×16 | 250 |

| OR-350 | 1180 | 990 | 76 | 140 | 180 | 11/4″ | 1″ | 30 | 12.5 | 175 | 130 | 13×16 | 350 |

| OR-600 | 1175 | 950 | 87 | 165 | 205 | T | 11/411 | 34 | 12.5 | 200 | 161 | 13×16 | 600 |

| OR-800 | 1700 | 1490 | 87 | 165 | 205 | T | 11/4“ | 34 | 12.5 | 200 | 161 | 13×16 | 800 |

| OR-1000 | 2140 | 1890 | 87 | 165 | 205 | T | 11/4″ | 34 | 12.5 | 200 | 161 | 13×16 | 1000 |

|

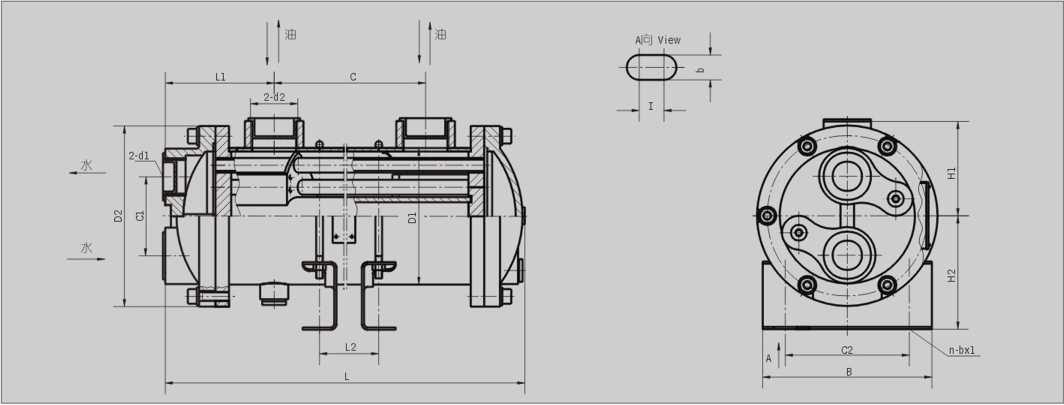

Model |

L |

Cl |

C |

L2 |

LI |

H2 |

B |

C2 |

n-b x I |

Hl |

D2 |

DI |

(12 |

dl |

Weight (Kg) |

| SL-303 | 305 | 45 | 152 | 107 |

80 |

85 |

115 |

75 |

4-11×20 | 64 |

120 |

87.9 |

G3/4 |

G3/4 |

4.5 |

| SL-304 | 377 | 224 | 179 |

5 |

|||||||||||

| SL-305 | 450 | 296 | 251 | 5.5 | |||||||||||

| SL-307 | 593 | 440 | 395 |

6 |

|||||||||||

| SL-309 | 737 |

584 |

539 |

7 |

|||||||||||

| SL-311 | 880 | 728 | 683 |

8 |

|||||||||||

| SL-408 | 467 | 75 | 284 | 240 |

94 |

100 |

150 |

110 |

4-10×20 | 85 |

160 |

121 |

G1 1/4 |

G3/4 |

14 |

| SL-411 | 610 | 428 | 384 |

17 |

|||||||||||

| SL-415 | 755 | 572 | 528 |

19 |

|||||||||||

| SL-418 | 900 | 716 | 672 |

22 |

|||||||||||

| SL-421 | 1042 | 860 | 816 |

25 |

|||||||||||

| SL-512 | 528 | 70 | 298 | 206 |

121 |

140 |

180 |

135 |

4-18×25 | 95 |

180 |

139.8 |

G1 1/2 |

G1 |

20 |

| SL-518 | 635 | 406 | 342 |

22 |

|||||||||||

| SL-526 | 852 | 622 | 558 |

27 |

|||||||||||

| SL-534 | 1070 | 838 | 774 |

32 |

|||||||||||

| SL-542 | 1285 |

1054 |

990 |

38 |

Note: our company can manufacture all kinds of large and special coolers according to the requirements of customers.

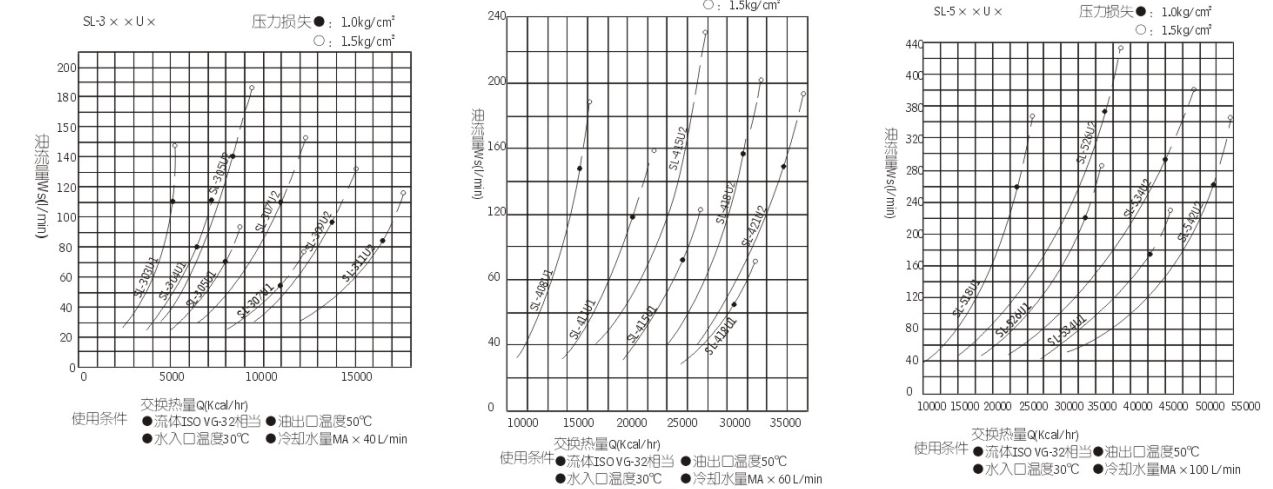

1. Calculate the heat required to exchange:

Q(Kcal /h) (1) Calculate according to the temperature requirements and flow of the oil: Q is CW of N dot T2.In the formula, the specific heat of C oil (kCa L/kg°C) W — the flow rate of oil (kg/h)T1 — inlet oil temperature (°C) T2 — outlet oil temperature (°C)Among them: W = qPIn the formula, Q — flow rate of oil (IV min) P — density of oil (kg/L)According to the calorific value of the hydraulic system: Q = Pr-Pc-PhcWhere, PR is the input power of the hydraulic system PHC one tank, pipe heat dissipation power PC – output effective power.

2. Select the cooler model

Check the product performance curve according to the calculated heat exchange Q and oil flow Ws, and the intersection point of the two is the selected model.

3. Supplementary Notes

The actual operating conditions of the cooler may differ from their performance test conditions. The oil viscosity is small, the water flow is large, the temperature difference between the oil temperature and the water temperature is large, the model can be selected to be smaller than the selected model, on the contrary, the model is selected to be large.

Product detail pictures:

Related Product Guide:

Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for Original Factory Hydraulic Oil Level Indicator - OR-MULTI-TUBE Series Oil Pressure Cooler – Xinyuan , The product will supply to all over the world, such as: French, Boston, Bangkok, Now, with the development of internet, and the trend of internationalization, we've got decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.