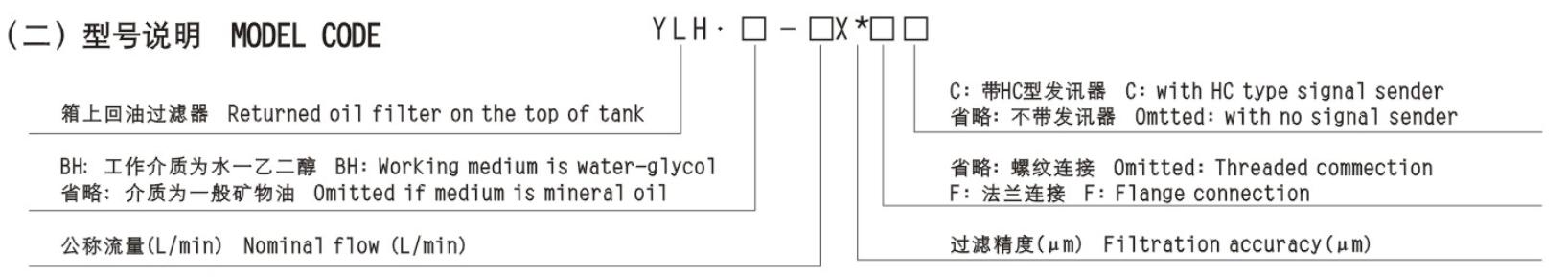

Ylx Series Return Filter On Oil Tank

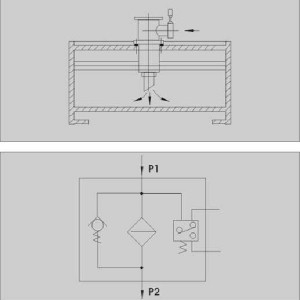

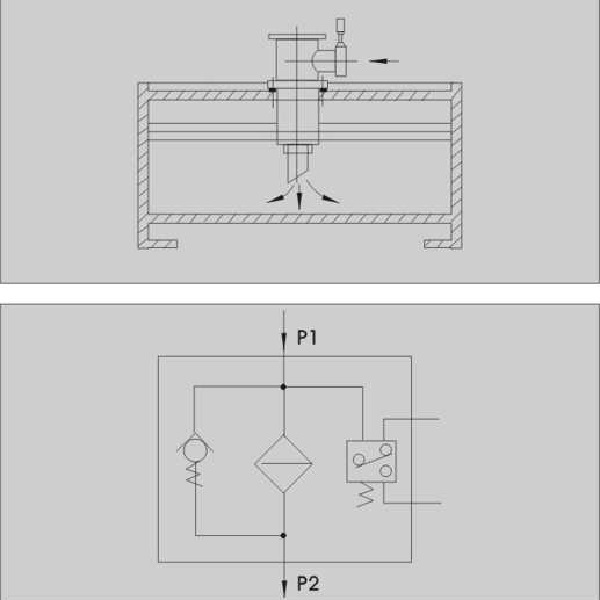

This filter is suitable for hydraulic system oil return fine filtration, uses in filtering hydraulic system because of, the metal particle which the component wears produces and seals the rubber impurity and so on contaminant, causes to return to the oil tank, the oil fluid maintains the cleanness. The filter is equipped with a transmitter, by-pass valve and a dirt trap.

The main performance features are:

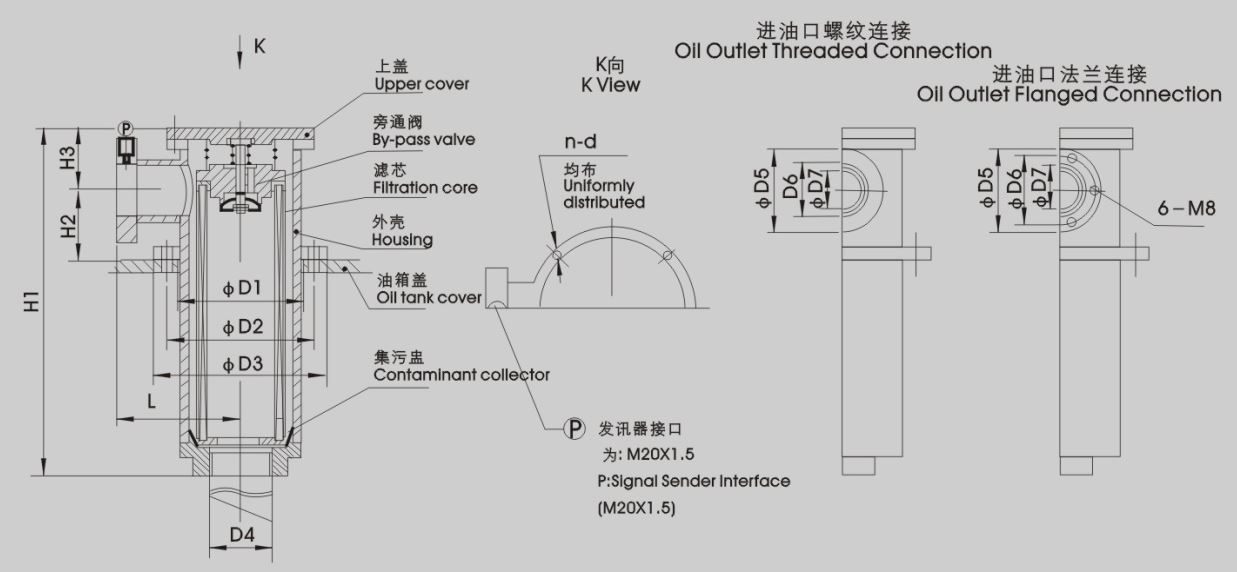

1. The filter is directly arranged on the fuel tank cover plate, and the cylinder body extends into the oil of the fuel tank. The oil inlet is provided with a screw thread and a flange connection mode, and is connected with an oil return pipeline. The pipeline is simple and convenient to install.

2. When the filter block, just open the top cover, can take out the filter core, when the replacement of the filter core, install the top cover, can be put into operation, very convenient.

3. A filter element is arranged at the oil inlet of the filter to block the transmitter, which has the functions of direct viewing and sending signals. By observing the indicator of the transmitter, the blockage of the filter element can be known at any time. When the filter element is blocked and the pressure of the oil inlet reaches the specified value in the technical parameter list, the transmitter will send out a signal and the filter element should be replaced immediately.

4. An oil by-pass device is provided. When the filter element is blocked and the transmitter can not be handled immediately after an alarm is given, a fault occurs. When the pressure at the oil inlet rises to the specified value in the technical parameter list, the by-pass valve will open by itself and a separate oil path will be opened to protect the filter from damage, make sure the system's still running.

5. During the operation of the filter, the pollutants filtered by the filter element are concentrated in the collection and pollution cup arranged in the filter element. When replacing the filter element, it can be carried out with the filter element to avoid the filtered contaminant falling into the oil tank o

6. Filter. The core adopts a new type of chemical fiber filter material, which has the advantages of high filtering precision, high oil-passing ability, low pressure, low loss and large pollution-receiving capacity.

The Model YLH filter is used for refined filtration of returned oil from the hydraulic system. Chemical fiber or glass fiber is used as the filtration core. The filter is equipped with a signal sender and by-pass valve. When the filter is clogged and the vacuum upto the stipulated value in the specifications, alarmwill be given.

| Parameters Model | Fomina' Dla. (mm) | Nominal Flow (L/min) | Filtration Accuracy (urn) | Nominal Pressure | Initial Pressure loss |

|

|

|||||

| YLH-10X*LC | 10 | 10 | 135

10 20 30 40 |

1.6 | <0.01 |

| YLH-25X*LC | 15 | 25 | |||

| YLH-63X*LC | 25 | 63 | |||

| YLH-100X*LC | 32 | 100 | |||

| YLH-160X*LC | 40 | 160 | |||

| YLH-250X*FC | 50 | 250 | |||

| YLH-400X*FC | 65 | 400 | |||

| YLH-630X*FC | 80 | 630 | |||

| YLH-8OOX*FC | 90 | 800 | |||

| YLH-1000X*FC | 100 | 1000 | |||

| YLH-1250X*FC | 110 | 1250 | |||

| YLH-1600X*FC | 125 | 1600 | |||

| Allowed Max. Pressure loss | By-pass Opening Pressure | Pressure upon Signal-sending | Signal Sending Power | ConnectionMode | Filtration Core Mode |

| (MPa) | |||||

| 0.35 | >0.37 | 0.35 | DC: 240V/480WAC: 220V/50W | Threaded | H-X10X* |

| H-X25X* | |||||

| H-X63X* | |||||

| H-X100X* | |||||

| H-X160X* | |||||

| Flanged | H-X250X* | ||||

| 0.22 | >0.27 | 0.22 | H-X400X* | ||

| H-X630X* | |||||

| H-X800X* | |||||

| H-X1000X* | |||||

| H-X1250X* | |||||

| H-X1600X* | |||||

Note: "'Indicates filtration accuracy, If the used medium Is water-glycol and the flow Is lOOL/mln, the flltraccuracy Is 3um. The model of the filter with the signal sender is YLH • BH-100X3C.

|

Model |

DI |

D2 |

D3 |

D4 |

D5 |

D6 |

D7 |

Hl |

H2 |

H3 |

L |

n-d |

| YLH-10X*LC |

87 |

115 | 135 | Gl/2" |

55 |

M18X1.5 |

15 |

165 |

50 |

60 |

110 | 4-巾7 |

| YLH-25X*LC | 112 | 140 | 160 | G3/4" |

60 |

M22X1.5 |

19 |

185 |

120 | |||

| YLH-63X*LC | 132 | 160 | 180 |

Gl" |

70 |

M33X2 |

27 |

250 |

60 |

65 | 135 | 4-巾9 |

| YLH-100X*LC |

GPA" |

80 |

M42X2 |

35 |

350 |

|||||||

| YLH-160X*LC | 150 | 180 | 200 |

G1V2" |

85 |

M48X2 |

41 |

360 |

65 |

70 |

140 | |

| YLH-250X*FC | 164 | 190 | 210 |

G2" |

100 |

85 |

53 |

490 |

70 |

76 | 160 | |

| YLH-400X*FC | 172 | 200 | 220 | G2 %' |

116 |

100 |

66 |

628 |

80 |

80 |

165 | |

| YLH-630X*FC | 198 | 225 | 245 |

G3" |

130 |

116 |

80 |

730 |

90 |

90 |

180 | |

| YLH-800X*FC | 250 | 270 | 285 |

750 |

6-巾9 | |||||||

| YLH-1000X*FC | 250 | 272 | 292 | M120X2 |

185 |

164 |

125 |

750 |

135 |

130 |

150 |

6-巾 11.5 |

| YLH-1250X*FC |

900 |

|||||||||||

| YLH-1600X*FC | M140X2 |

136 |

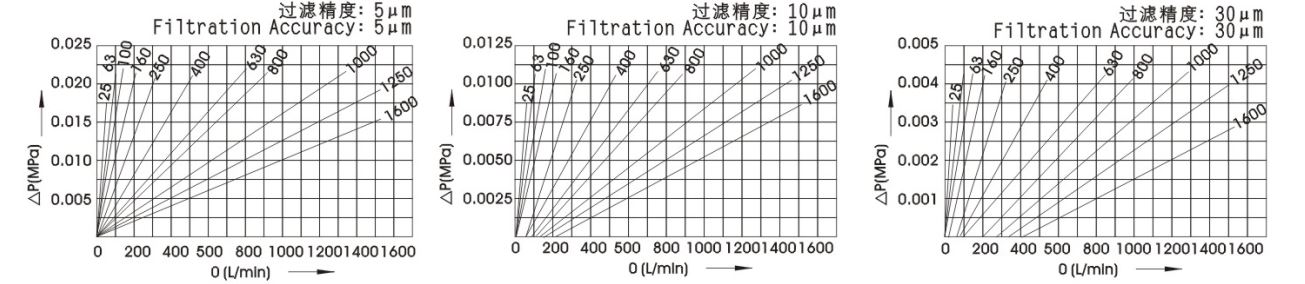

Q-AP Q-Characteristic Curve

YLH-25~1600 / 30mm2/S (CST)

(The curve Is drawn according to the data obtained from test) Product: YLH-50-1600 Oil Viscosity: 30mm2/S (CST)